OVERMOULDING & INSERT MOULDING

Overmoulding is a unique injection moulding process that results into seamless combination of multiple materials into a single part or product. It typically includes a rigid, plastic-base component overlaid with a thin, pliable, rubber-like thermoplastic elastomer or other materials(insert molding) using a single shot or multiple shot moulding technique.

Why choose Lunar Enterprise?

We have more than 45 years of experience in Injection Moulding. When you visit our workshop, you can find retro-grade injection moulding machines as well as hi-tech injection moulding machines which are industry-4.0 ready and robot-enabled. We have machines specifically designed for insert moulding which ensures mould safety.

We also offer secondary services to fulfill the entire manufacturing needs at one place.

How does over-moulding work?

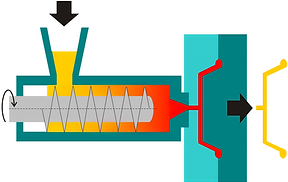

Injection molding, the most popular process for manufacturing thermoplastic products, consists of injecting molten plastic material from a heated cylinder into a closed mold, allowing the plastic to cool down and solidify, and ejecting the finished product from the mold. The machine consists of an injection unit to inject the material, and a clamping unit that is used to hold the mold closed during the injection phase.

Mould safety in insert moulding

If the hardness of the insert is more than the hardness of the mould, there are chances that the insert will damage the mold if not operated properly. Our machines specifically design for injection moulding keeps mould safe at all times.

Why choose over-moulding or insert moulding for your project?

-

It allows materials to be combined to provide characteristics that no single resin can deliver.

-

It can eliminate assembly steps, saving both time and money.

-

It can meld materials in a way that assembly processes cannot match.

-

Inserts add strength and durability to parts.